Description

FAG 33205 Tapered roller bearingSingle row Metric size |

|

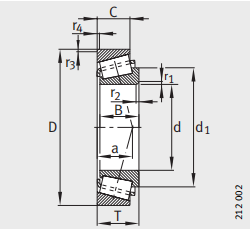

| Designation | Mass | Dimension | ||||||||

| m | d | D | B | C | T | r1,r2 | r3,r4 | a | d1 | |

| ≈kg | mm | mm | mm | mm | mm | min | min | ≈ | ≈ | |

| 33205 | 0.214 | 25 | 52 | 22 | 18 | 22 | 1 | 1 | 14 | 39.6 |

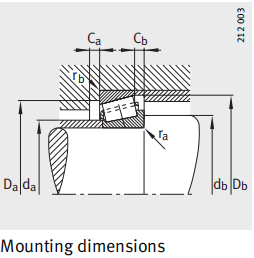

FAG 33205 Mounting dimensions |

|

| Designation | Mounting dimensions | ||||||||

| da | db | Da | Da | Db | Ca | Cb | Ra | rb | |

| max | min | min | max | min | min | min | max | max | |

| 33205 | 30 | 31 | 43 | 46 | 49 | 4 | 4 | 1 | 1 |

| Designation | Interchange designation to ISO 355 | Basic load ratings | Calculation factors | Fatigue limit load | Limiting speed | Reference speed | |||

| dyn | stat | e | Y | Y0 | Cur | nG | nB | ||

| Cr N | C0r | N | min-1 | min-1 | |||||

| 33205 | T2DE025 | 48 500 | 58 000 | 0.35 | 1.71 | 0.94 | 6 900 | 14 000 | 7 200 |

Features

Tapered roller bearings comprise solid inner and outer rings with tapered raceways and tapered rollers with cages made from pressed sheet steel. The bearings are not self-retaining.

As a result, the inner ring with the rollers and the cage can be fitted separately from the outer ring.

Radial and axial load capacity

Tapered roller bearings can support axial forces in one direction and high radial forces. They must normally be axially adjusted against a second bearing fitted in a mirror image arrangement. This bearing combination is fitted in an O or X arrangement.

Cages

Tapered roller bearings have pressed cages made from sheet steel.Since these project laterally to a certain extent, the mounting dimensions in the dimension tables and the cage projection must be observed.

Operating temperature

Tapered roller bearings can be used at operating temperatures from –30 °C to +120 °C. Bearings with an outside diameter of more than 90 mm are dimensionally stable up to +150 °C, bearings with an outside diameter of more than 120 mm up to +200 °C.